Wood Line Vacuum Spray Painting Machineis a device designed for applying water-based paints efficiently and evenly. It operates by creating a vacuum that draws the paint into a spray mechanism, which then atomizes the paint into fine droplets. These droplets are propelled onto the surface to be coated, ensuring a smooth and uniform finish. The machine is particularly suitable for water-based paints, which are environmentally friendly due to their low volatile organic compound (VOC) content.

Basic configuration

| Minimum working length | 400mm |

| Maximum working width | 300mm |

| Maximum working thickness | 70mm |

| Minimum working thickness | 8mm |

| Total power | About 45KW (full load) |

| Blower power | 15KW (frequency control) |

| Conveyer power | 0.75KW |

| Feed speed | 0 – 40 meters / minutes |

| Electric heating power | 6KW×1(2) |

Function

Vacuum spray painting

3 sides painting and 4 side painting

UV paint or water base paint

share:

Description

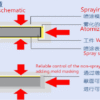

Uniform Coating with Vacuum Atomization

Wood line vacuum spray painting machine uses a controlled vacuum process to atomize water-based paint into fine droplets, creating an even and smooth finish on different workpiece profiles. This technique increases coating uniformity across large or small surfaces while keeping efficiency stable during continuous operation. As a solution built by an experienced cnc router manufacturer, Samdy incorporates process reliability and mechanical accuracy into every design stage. With compatibility for low VOC coatings, it reflects the environmental standards upheld by leading woodworking cnc machine manufacturers, providing consistency, reduced waste, and higher quality finishes in professional applications.

Adjustable Film Thickness for Precision Finishing

Operators can adjust coating thickness within a range of 20 to 80 grams per square meter, allowing flexibility for different surface protection requirements. The adaptability ensures that single, three, or four sides of a workpiece can be coated effectively with equal stability. Components sourced from Taiwan and Switzerland improve durability, reduce maintenance, and enhance machine reliability during extended use. This precision highlights Samdy’s expertise as a cnc wood router supplier that values both performance and lifespan. By integrating global-quality parts, the company aligns with user expectations from router cnc systems that demand strong consistency and professional-grade output.

Reliable System with Practical Functions

The equipment combines power efficiency with labor savings by equaling the productivity of four manual sprayers, reducing operating pressure on staff. Its blower, heating, and conveyor systems integrate seamlessly to manage coating speeds of up to 40 meters per minute, supporting high-capacity lines. Stainless steel spray boxes with automatic water flushing simplify daily cleaning and minimize downtime, helping operations run smoothly. These features demonstrate how Samdy, recognized for 4×8 cnc router and advanced woodworking technologies, continues to expand in precision manufacturing. It highlights the value expected from a woodworking cnc machine provider that delivers durable, efficient, and easy-to-maintain solutions.

Use Scenarios

Outdoor Furniture Surface Treatment

The spray machine is suitable for outdoor furniture items such as wooden chairs, benches, and tables, where water-based paint and wood wax oil are often required to extend service life. Its adjustable film thickness ensures coatings can be applied for durability against changing outdoor conditions while maintaining surface smoothness. This versatility reflects the solutions offered by a professional cnc table router partner. By linking finishing reliability with dependable equipment design, Samdy provides a machine that matches expectations for industries also using cnc router aluminum systems.

Interior Panel and Mold Coating

With options to coat one, three, or four sides of wood-based panels, the equipment supports interior applications such as wall components, decorative moldings, and flat boards requiring high-quality finishes. Mold customization ensures surfaces can be matched precisely to specific profiles, improving final results. This adaptability demonstrates the range associated with a large cnc router supplier that understands how coating integrates with other machining processes. Samdy extends its reputation as a cnc router for aluminum partner by delivering finishing equipment that supports workflows where precise surface treatments are essential.

Continuous Industrial Coating Lines

The combination of a conveyor running up to 40 meters per minute, stainless steel spray boxes, and automated cleaning allows the machine to integrate smoothly into continuous industrial coating lines. These features reduce downtime, save labor costs, and maintain reliable surface treatment across large production volumes. This reflects the standards expected from advanced cnc router machines suppliers who focus on workflow efficiency. With proven experience as a cnc woodworking machine manufacturer, Samdy positions the spray equipment as an industrial solution for companies requiring productivity, environmental safety, and dependable long-term performance.

Machine advantage

1.Energy saving.Coatings is over 97%, which is 60% less than that of manual spraying.

2.Environmental protection. Atomizing coatings are recycled in quasi closed space without leakage or emission, which is more environmentally friendly and healthy.

3.Saving labors. This machine is equivalent to four mature sprinters

4.Simple operation. Painting film thickness adjustment range is 20 – 80 grams / m2.

5.Quality assurance. The core component is Taiwan origin, with frequency conversion speed adjustment, easy to adjust. The press device is ROSTA, Switzerland .

6.Practical. You can chose any side surface to do painting, more practical. 4 sides painting ,3 sides painting or single side painting are optional.

Spray painting side surface

Painting sides are optional

You can change the mold to control which sides you want to do painting.

Working Piece Mould

Wood line design mould

The mould is made according to wood line’s design and size to make sure the vacuum working environment.

Spray Painting Box

Easy to clean

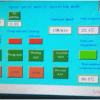

Stainless Steel material is easy to clean,just need to add water then press clean key in touch screen,the cleaning will be finished.

SHILIN Brand Inveter

15 kw

Durable service.

Paint Filter

filt out impurities

The paint utilization rate is more than 97%, saving about 60% paint than manual spraying. Film thickness 20-80g /m² can be adjusted.

Finished Painting Products

4 sides painting is available

Water base paint and wood wax oil can be used on this machine ,it is suitable for outdoor furniturn painting,such as outdoor chairs,outdoor wooden flooring ect.

CONTACT US

If you have any queries, get in touch today! Don’t hesitate. We try to take the extra step for our customer satisfaction.

CONTACT US