SV-468J

Full automatic PVC edge banding machine SV-468J is with pre-milling function , double trimming and corner rounding, to remove the broken cutting edge and give you a good corner profile.It can meet all requirements for panel furniture.This is best choice for furniture factory.

Edge banding machine is to apply a strip of edge banding material (such as PVC, ABS, wood veneer, or melamine) to the exposed edges of panel materials like particleboard, MDF, or plywood.

Basic configuration

Workpiece length: ≥200mm

Workpiece width: ≥60mm

Workpiece thickness: 10-60mm

Covering tape thickness: 0.3-3mm

Working air pressure: 0.7Mpa

Total power :16KW

Machine size:6700*1000*1600mm

Function

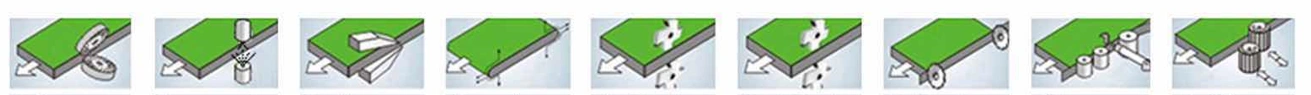

Separation-double motor pre-milling-Gluing-End cutting-Rough trimming-Fine trimming-Corner rounding–scraping-cleaning-Buffing(Automatic lifting)

share:

Description

Full Processing With Integrated Functions

Full automatic PVC edge banding machine SV-468J is a fully automatic machine designed to apply PVC, ABS, veneer, or melamine tape on MDF, particleboard, or plywood edges. It combines premilling, gluing, end cutting, rough trimming, fine trimming, double trimming, scraping, corner rounding, buffing, and slotting into one process. It supports panel length ≥120mm, width ≥80mm, thickness 10–60mm, and tape thickness 0.4–3mm. For companies sourcing from trusted woodworking cnc machine manufacturers, the integrated premilling ensures a smooth surface for accurate tape bonding.

Stable Operation With Reliable Components

The equipment is equipped with Taiwan Shilin PLC, inverter, and touch screen, together with Schneider contactors for consistent control. The pressing beam uses electric lifting, and the rollers—three metal and one rubber—apply even pressure. A heavy-duty body enhances stability during extended use. Options such as PUR gluing and pneumatic adjusting cutter tooling expand flexibility. For workshops comparing suppliers among cnc router manufacturers, this reliable structure ensures long-term operation. When paired with a cnc router table, the machine maintains stable bonding and trimming across production runs.

Accurate Trimming And Corner Rounding

The trimming unit uses R knives with dual 0.75KW motors, leaving allowance for scraping. Double trimming ensures smooth panel edges, while corner rounding refines angled corners for uniform results. Buffing and hot air systems improve surface quality, and the gluing pot’s two-layer design offers good heat dissipation and durability. Manual lifting of the glue pot allows simple adjustments. As part of a production line from an experienced cnc router manufacturer, the SV-468J complements cnc router bits by ensuring that cut edges are finished with accuracy and durability.

The trimming unit features R knives powered by dual 0.75KW motors, leaving an allowance for scraping and ensuring smooth shaping. Double trimming enhances precision along both upper and lower panel edges. Buffing creates a polished surface, while the glue pot has a two-layer design that provides heat dissipation and durability. Manual lifting of the glue pot makes adjustment straightforward. For companies investing in equipment from an experienced cnc router manufacturer, these functions complement cnc router bits to guarantee clean edges after cutting.

Product Advantages

Automatic model give you good edge banding and high output capacity,save time and labor.

Use Scenarios

Cabinet and Furniture Manufacturing

Machine advantage

1.Taiwan Shilin PLC,Taiwan Shilin Inveter ,Taiwan Shilin touch screen and Schneider contactor to ensure machine working stable.

2.Pressing rollers with flat knife,to make more perfect edge banding surface.

3.Heavy duty machine body to ensure machine is dural.

4.Good price.

5.PUR gluing and pneumatic adjuting cutter tooling are optional.

Full Automatic PVC Edge Banding Machine SV-468J Touch Screen

Taiwan China Shilin Brand

PLC and Inveter

Taiwan China Shilin Brand

Famous Brand Contactor

Franch Schneider brand

Reliability & Durability & Safety.

Dual Motors Pre-milling

2.2kw x2 pcs

Press Rollers With Scraper

6 pressing rollers

It makes the pressing more perfect,rubber roller will make pressing more even.

Double Trimming

Rough trimming & fine trimming

Corner Rounding

2 heads corner rounding

Dual motor tracking, used for arc trimming of corners.

Using 0.37*2 motor.

4-head corner rounding is optional.

Scraping and buffing

Scraping and dual motor buffing

After trimming, scrape off the residue on the board and edge band again to ensure that the board and edge band are smooth and clean, making the edge band effect smoother. The polishing and waxing device effectively solves the problem of whitening of the edge band, making the edge band effect more perfect.

Edge Banding Effect

0.4-3MM is available

Good edge banding effects make your furniture better.

CONTACT US

If you have any queries, get in touch today! Don’t hesitate. We try to take the extra step for our customer satisfaction.

CONTACT US