SV-568-PUR

Economic automatic edge banding machine SV-568-PUR-2 is also special edge bander for aluminum furniture,special pressing unit,special corner rounding and special pressing belt give you good aluminum furniture looking.

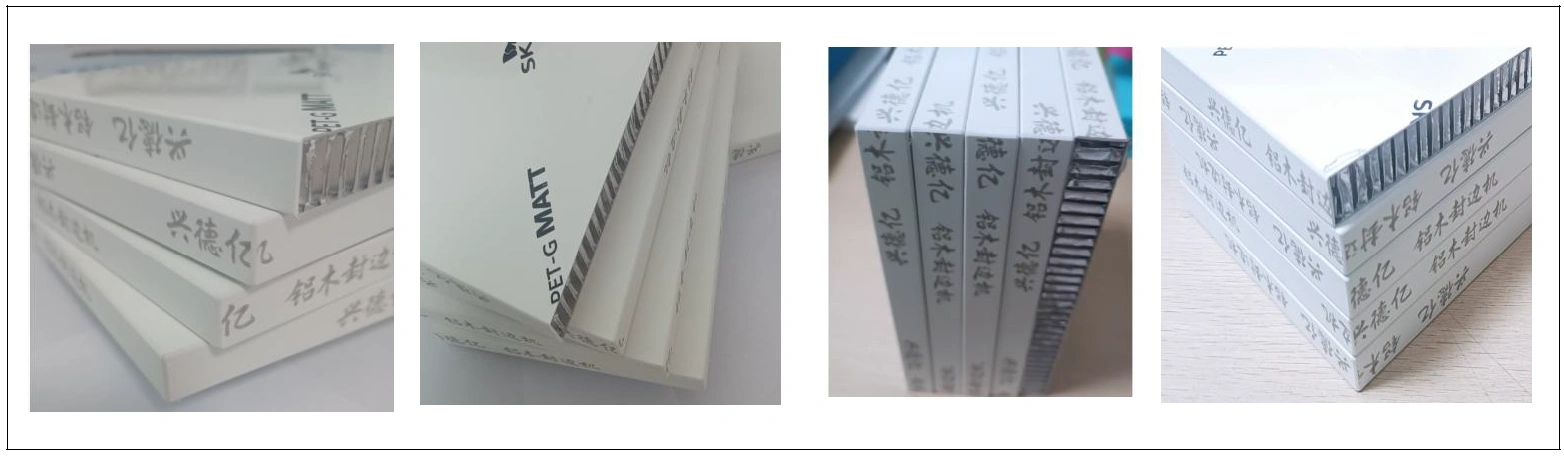

The trend of all-aluminum home furnishings is gaining momentum due to its numerous advantages. Aluminum is lightweight, durable, and resistant to corrosion, making it an ideal material for modern furniture.

Basic configuration

Workpiece length: ≥200mm

Workpiece width: ≥80mm

Workpiece thickness: 10-60mm

Covering tape thickness: 0.3-3mm

Working air pressure: 0.7Mpa

Total power:22.5KW

Function

Separation-double motor pre-milling-PUR gluing pot plus two color PUR melting machine -6 pressing roller-belt pressing-rough trimming-fine trimming-single guide rail end cutting-four motor corner rounding-scraping-flat scraping-spray cleaning-buffing 1-buffing

share:

Description

Cost-Effective PUR Adhesive Solution

Economic automatic edge banding machine SV-568-PUR economy model applies PUR adhesive through a dual-barrel system, designed for consistent edge bonding on aluminum honeycomb furniture panels. It supports workpieces with a minimum length of 200 mm, width from 80 mm, and thickness between 10–60 mm. With a capacity for solid edge bands up to 2 mm, it provides versatility for different panel applications. This configuration is practical for manufacturers using Cnc Router or Cnc Router Machine equipment where precise bonding complements panel cutting. The design ensures reliable adhesion while offering an economical solution for continuous use in woodworking and composite processing.

Integrated Trimming And Control Units

The machine is equipped with rough and fine trimming systems, an end cutting station, and four-head corner rounding. Together with scraping and buffing, these functions provide smooth, refined surfaces. A Taiwan Shilin PLC, Schneider contactor, and user-friendly touch screen enhance operational stability and ease of control. This integration benefits facilities that rely on Woodworking Cnc Machine Manufacturers equipment or Cnc Woodworking Machine systems, where combining routing and edge banding improves efficiency. The consistent trimming and stable control platform minimize rework while ensuring high-quality output in demanding production environments.

Structural Strength And Power Capacity

With a heavy-duty body and total installed power of 22.5 KW, the 568-PUR-2 offers strength for industrial use. The reinforced structure reduces vibration, improving bonding accuracy and surface consistency. Its design is particularly suited for large-scale facilities using Cnc Router Table units or Industrial Cnc Router systems, where strong mechanical stability is required for extended production cycles. By supporting continuous panel handling with durability and power, the machine aligns with the needs of professional manufacturers producing aluminum honeycomb or composite panels at scale

Product Advantages

Dual-Barrel PUR System

The dual-barrel PUR configuration enables quick replacement of adhesive cartridges and maintains bonding quality during extended operation. This system ensures continuous edge finishing performance and reduces downtime in production. Factories integrating Cnc Router Kits or Cnc Machine Woodworking setups benefit from a stable adhesive process that supports long runs without quality loss. By minimizing adhesive interruptions and supporting smooth panel transitions, the dual-barrel arrangement helps operators maintain productivity across shifts, making it practical for workshops where stability and efficiency are equally important.

Economical And Durable Machine Design

The 568-PUR-2 offers an economical edge banding solution without sacrificing durability. Its reinforced frame and optimized functions provide lasting performance, making it suitable for facilities balancing cost and quality. Workshops using Router Cnc or 4×8 Cnc Router setups can incorporate this machine for reliable bonding while maintaining lower investment levels compared to higher-spec models. The structure ensures dependable performance even under frequent use, offering manufacturers an affordable entry point to advanced PUR edge banding technology while still delivering industrial-level stability and efficiency.

Complete Edge Finishing Capability

From pre-milling preparation to gluing, trimming, corner rounding, scraping, and buffing, the machine delivers a full finishing line in one platform. Each stage contributes to improved edge quality and reduced error rates. Manufacturers combining Cnc Router Bits For Wood or Large Cnc Router operations can achieve professional edges that match industrial standards, while maintaining speed and consistency in production cycles. The ability to integrate multiple finishing processes into one machine saves floor space, lowers labor needs, and improves coordination with upstream and downstream equipment.

Use Scenarios

Aluminum Panel Processing

Ideal for manufacturers who work with aluminum honeycomb panels, the machine provides efficient edge bonding. Facilities using cnc router aluminum systems or cnc router for aluminum setups can rely on the PUR technology to create secure finishes for lightweight yet rigid materials. These panels often serve demanding industries, and the machine’s ability to maintain strong adhesive bonds helps ensure performance standards are consistently met while minimizing waste from rejected parts.

Cabinet and Furniture Manufacturing

In workshops producing furniture or cabinetry, especially those utilizing cabinet edge banding machine solutions alongside a 4×4 cnc router, the machine contributes to clean and durable finishes. Its consistent application of PUR adhesive ensures panel edges remain stable through use and handling. This makes it suitable for manufacturers requiring repeatable outcomes on a daily basis, helping to maintain production flow while delivering products with professional surface finishes that meet consumer expectations for durability.

Industrial Woodworking Lines

Large production sites that operate industrial cnc router systems or cnc drilling machine units benefit from incorporating this edge banding solution. The machine’s capacity for stable bonding supports continuous workflows, making it suitable for facilities demanding uniform edge quality in high-volume operations. By enhancing consistency, it helps reduce the likelihood of defects and aligns with production strategies where efficiency, reliability, and high output are priorities for woodworking and panel-based industries.

Machine advantage

1.Taiwan Shilin PLC,Taiwan Shilin Inveter ,PC screen and Schneider contactor to ensure machine working stable.

2.Pressing rollers with flat knife unit and pressing roller belt unit,to make more perfect aluminum panel edge banding surface.

3.Heavy duty machine body to ensure machine is dural.

4.Good price.

5.Four-head corner rounding can do more fast ,movement is lightly,to avoid damaging the honeycomb panels.

Economic Automatic Edge Banding Machine touch Screen

10 inch size

PLC and Inveter

Taiwan China Shilin Brand

Famous Brand Contactor

Franch Schneider brand

Reliability & Durability & Safety.

Dual Motors Pre-milling

2.2kw x2 pcs

Press Rollers With Scraper

6 pressing rollers

It makes the pressing more perfect,rubber roller will make pressing more even.

Pressing belt

Special pressing construct for aluminum honeycomb panels.

PUR Gluing Unit

equiped with PUR glue melt machine

Rubber Belt

Use rubber belt to replace of normall rubber roller

Trimming units

Rough trimming and fine tirmming

The fine trimming function uses the R trimming knife to trim the curvature of the board edge banding. The fine trimming will also leave a margin for the subsequent scraping function. The two sets of fine trimming are convenient for free switching according to the different thicknesses of the workpieces.

Dual End Cutting

0.37KW*2pcs

valve). The air pressure is more stable and the ends are aligned

more stable.

Heavy duty FRL

air filter (F), Air pressure (R), and lubricator (L).

Scraping and buffing

Scraping,polishing,bufffing

CONTACT US

If you have any queries, get in touch today! Don’t hesitate. We try to take the extra step for our customer satisfaction.

CONTACT US