CS-6-2800

CNC door wall panel cabinet machine is a production tool that efficiently and accurately transforms design data into physical components through digital, automated, and process-centralized processing methods.

Basic configuration

Max working thickness: 60mm

Max working length: 2800mm

Max working width: 150mm

Working table size:500*2800mm

Working speed: 60m/min

Vertical spindle:6kw *1

Horizontal spindle:6kw*1 2.2kw*1

45 degree spindle :3.5kw*2

Total power: 25.5kw

Machine size:4600*1800*1800mm

Machine weight:1200kg

Function

Cutting,drilling,side drilling,grooving,milling,door lock hole,hinge hole,pull & handle hole.

share:

Description

CNC door wall panel cabinet machine integrates multiple processing heads and can sequentially complete all of the following operations:

1. Cutting: Precisely cuts panels.

2. Drilling: Processes various connector holes (such as three-in-one connectors, hinge holes), shelf pin holes, functional component holes, etc.

3. Milling: Carves complex contours (such as door shapes, decorative lines), grooves, hollows, beveling, etc.

4. Edge Banding (integrated in some high-end models): Automatically completes edge banding of panels, even seamless edge banding.

5. Inkjet Printing/Marking: Automatically marks component numbers for easy subsequent sorting and installation

Use Scenarios

CNC door wall panel cabinet machine is a core production tool specifically designed for custom home furnishing factories, used to produce:

• Whole-house custom furniture: Wardrobes, cabinets, bookcases, and all panel cabinets.

• Interior doors: Flat doors, openwork doors, etc.

• Wall panel/wainscoting systems: Integrated wall panels in various styles.

• Other wooden components: Such as countertops, decorative pieces, etc.

Machine advantage

- Multi-Spindle Drilling Units: Typically features multiple independently controlled drill heads (often 3-10+), allowing simultaneous drilling of several holes at different positions along the panel edge.

- CNC Control System: The brain of the machine, interpreting CAD/CAM files and precisely controlling the position of the drill heads and workpiece movement.

- Programmable Drill Heads: Individual drill heads can move independently along the X-axis (panel length) and often rotate to drill at precise angles (typically 0° to 90° relative to the surface).

- Automatic Tool Changers (Optional): Higher-end models may automatically swap drill bits for different hole sizes within a single program.

- Precision Linear Guides & Servo Motors: Ensure smooth, accurate, and rapid positioning of the drill units.

- Robust Clamping System: Securely holds panels of various sizes and thicknesses in place during drilling.

- Dust Extraction System: Built-in ports connected to a dust collector.

- Touchscreen HMI (Human-Machine Interface): For easy programming, job selection, monitoring, and machine control.

- Sensors: For detecting panel position, thickness, and potential errors.

Drilling Spindle

5 spindles (2 horizontal heads +1 vertical head+2 45 degree heads)

Vertical spindle:6kw *1

Horizontal spindle:6kw*1 2.2kw*1

45 degree spindle :3.5kw*2

Automatic Tool Setting

Vertical and Horizontal

Automatic positioning to ensure processing accuracy.

Position Cylinder

Movable pressing cylinder

8 groups of movable pressing cylinder to make sure pressing panel well during processing.

Precision Screw

High precision and stable

Screw drive ensures the accuracy and stability of machine processing.

Control System

Taiwan Baoyuan sytem

Baoyuan system is easy to operate,big size screen.

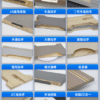

Finished Products

Multiple functions

Can process a variety of products to meet all your cabinet processing requirements.

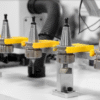

Automatic change cutters

6 cutters

6 automatic cutters tooling can meet different various processing requirements.

CONTACT US

If you have any queries, get in touch today! Don’t hesitate. We try to take the extra step for our customer satisfaction.

CONTACT US