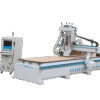

K6013-K12-T2

CNC center machine K6013-K12-T2 is for processing wood panel,plastics panel,acrylic sheet,aluminum honeycomb panel etc.It has Automatic change cutter function and 1 pc of saw blade. Saw blade cutting speed fast,suitable for cutting aluminum honeycomb panels.

It operates based on NC code production data, allowing for precise and automated cutting, carving, and engraving.

CNC routers are widely used in packaging industry, woodworking industry, furniture industry and advertising industry due to their accuracy and efficiency.

Basic configuration

Control System: Baoyuan bus system

Work Surface Size: 3100/2800 x 1250 mm

Spindle Parameters: 9KW x 1, Max Speed 24,000 rpm

Saw Blade Motor: 3KW x 2, Max Speed 6,000 rpm

Vacuum Pump: 7.5KW x 2 water cooling pump

Air Pressure Requirement: 0.7 Mpa

Total Power: 27KW

Working Table Quantity: 2 pcs

Overall Dimensions: 8000 x 2300 x 2200 mm

Function

Double working table

2 Spindle

Automatic change cutters(12 cutters)

1 pc of saw blade

share:

Description

CNC center machine K6013-K12-T2 is a high-performance CNC router designed for precision machining of aluminum honeycomb panels and other materials. Equipped with dual working stations, this machine enables simultaneous processing on both sides of the panel, significantly increasing production efficiency. The machine’s versatile capabilities allow for cutting, engraving, and milling operations, making it an ideal solution for complex manufacturing needs.

The K6013-K12-T2 offers exceptional precision and stability, ensuring that all machining tasks are completed with high accuracy. The dual working station design helps reduce downtime between operations and increases overall throughput, making it perfect for high-volume production. Additionally, the quick tool change feature minimizes interruptions and boosts productivity.

Equipped with an advanced Baoyuan bus system, the CNC router enables real-time monitoring and control of the production process, ensuring optimal performance at all times. This system allows users to easily control the CNC machine router, set parameters, and monitor progress, reducing the chances of human error and improving overall efficiency.

The robust construction of the K6013-K12-T2 ensures that it remains reliable even under heavy workloads. It is built to withstand the demands of industrial environments, offering a long lifespan and requiring minimal maintenance. Whether used in woodworking CNC machines, automotive manufacturing, or custom fabrication, this machine is well-suited for handling complex cutting tasks with high repeatability.

Use Scenarios

he CNC Samdy K6013-K12-T2 offers several significant advantages that make it an excellent choice for industries requiring high precision and efficiency in machining:

Dual Working Stations for Increased Productivity

The dual working station design enables simultaneous operations, reducing downtime and increasing overall production output. With the ability to work on both sides of a panel at the same time, this CNC router cuts processing time in half, making it ideal for high-volume production environments.

Versatile Tooling Configuration

The K6013-K12-T2 comes equipped with multiple tool holders, enabling quick tool changes and offering versatility for cutting, milling, and engraving applications. This flexibility makes the router ideal for a wide range of materials and applications, making it an incredibly versatile asset in any CNC router machine setup.

High Precision and Stability

This CNC router machine is designed to deliver exceptional precision and stability, even under the most demanding working conditions. The heavy-duty construction ensures minimal vibration and high accuracy, enabling the machine to produce intricate designs and tight tolerances required in industries like aerospace and automotive manufacturing.

Advanced Control System for Optimal Performance

The K6013-K12-T2 is equipped with the Baoyuan bus system, which allows for easy control, monitoring, and optimization of the CNC router operations. This advanced control system enhances productivity, reduces human error, and ensures consistent results throughout each production cycle.

Durability and Longevity

With a robust frame and high-quality components, this CNC router machine is built to last. It can withstand long hours of operation in industrial settings, making it a long-term investment for businesses that rely on continuous, high-precision production.

Easy Maintenance and Low Downtime

Designed for ease of use and minimal maintenance, the K6013-K12-T2 is easy to service, ensuring low downtime and high operational efficiency. The advanced components are built to last, and any necessary maintenance is straightforward, reducing the need for expensive repairs.

Machine advantage

Efficiency: The dual working stations and tool-changing capabilities ensure that the CNC Samdy K6013-K12-T2 is a high-efficiency machine, reducing downtime and increasing productivity in industries like aerospace, automotive, and custom fabrication.

Expertise: CNC Samdy has over 18 years of experience in designing and manufacturing high-quality CNC routers. The K6013-K12-T2 reflects our commitment to precision, innovation, and reliability, making it a trusted choice for businesses around the world.

Technology: With an advanced control system and high-quality components, the K6013-K12-T2 ensures optimal performance for complex machining tasks. Its robust build and innovative features allow it to handle high-demand tasks in industrial environments without compromising quality.

Affordability: The K6013-K12-T2 offers industrial-grade performance at a competitive price, making it a cost-effective solution for businesses that need reliable CNC router machines for high-volume production.

Ready to enhance your production with the CNC Samdy K6013-K12-T2? Don’t miss out on this high-performance CNC router that delivers precision, efficiency, and versatility. Contact us today to learn more about how the CNC Samdy K6013-K12-T2 can transform your production capabilities and help you achieve optimal results!

PC Screen

Taiwan baoyuan system

Esay operation.Industrial computer is also optional.

Electric parts

Good band

Driver:

Use Leadshine servo, matching the same brand of

motor use.

Frequency converter:

Use BST 6 KW frequency converter.

Contactor :

Schneider

Electronic hand wheel pulse generator

Easy commissioning

Zero correction and signal segmentation.

Vacuum adsorption table controller

8 pcs

Vacuum adsorption table is controlled separately,to ensure when process small workingpiece stable.

Gear Rack

Good quality and dural

The baffle is installed above the rack to effectively prevent dust and

debris from getting stuck on the rack, and to prevent the reducer from

shaking resulting in wavy patterns and other phenomena.

1 Spindles +saw blade spindle

9kw+3kw

It has Automatic change cutter function and 1 pc of saw blade. Saw blade cutting speed fast,suitable for cutting aluminum honeycomb panels,improve output capacity.

Positioning cylinder

Precise positioning

The whole machine uses seven positioning cylinders to facilitate the positioning of large or small plates.

Automatic change cutter

12 cutters

12 cutters in straight line tool package automatically switch to use, suitable for a variety of processing needs, convenient and fast.

CNC Center Machine Heavy Duty Machine body

20mm thick

The table top and the sides of the machine body are reinforced with 20mm thick cast iron in addition to the original structure.

Push device and dust collector cover

Push panels and dust removal device

Automatically push material after the completion of opening material, along with the removal of working table dust.

CONTACT US

If you have any queries, get in touch today! Don’t hesitate. We try to take the extra step for our customer satisfaction.

CONTACT US