A CNC six-sided drilling machine is a professional woodworking machine used to automatically drill precise holes on six sides of a workpiece (usually a board). It can complete multi-sided processing in a single setup, significantly improving the production efficiency of cabinets and office furniture, and ensuring the dimensional accuracy and consistency of assembled parts.

Basic configuration

System: Taiwan Baoyuan System; Servo System: LESAI Servo;

Number of Spindles: 4 (2 vertical and 2 horizontal);

Spindle Parameters: 4.5 kW, maximum speed 18000 rpm;

Drilling Assembly Parameters: 2.2 kW, maximum speed 4500 rpm, 7 vertical holes + 2 horizontal holes;

Workpiece Length: 70-2440 mm;

Workpiece Width: 50-850/1220 mm;

Workpiece Thickness: 9-40 mm; Maximum Power: 31 kW

Function

Six-sided drilling, grooving, and simple milling.

share:

Description

This full-surface drilling CNC

six-sided drilling machine is designed for comprehensive sheet metal processing, supporting vertical and horizontal drilling on all six sides of a workpiece. It can process sheets with lengths of 70–2440 mm, widths of 50–850/1220 mm, and thicknesses of 9–40 mm. With its versatile processing range, this system can be used for pre-processing hinges, connectors, or mounting slots in furniture panels. Integration with CNC engraving machines or CNC milling machines enables manufacturers to automate complex drilling tasks that previously required multiple clamping operations, thereby improving the accuracy of industrial woodworking and reducing processing time.

Stable system, precise control.

This model adopts the Taiwan Baoyuan CNC system and Leadshine servo drives, providing reliable control and stable motion performance. Equipped with four 4.5kW spindles and two 2.2kW drilling units, it ensures powerful and precise output of drilling patterns. The total installed power of 31kW supports continuous heavy-duty operation. This system optimizes the workflow of woodworking CNC machine tool manufacturers’ resources or CNC woodworking machine tool processes, coordinating drilling with milling, cutting, and edge banding processes. It reduces errors caused by manual marking, ensuring consistency in mass production.

Automation For High-Volume Production

An automatic loading and unloading conveyor system enables seamless feeding, allowing continuous panel processing with minimal manual intervention. The system’s ability to carry out vertical holes, horizontal holes, and grooving in a single pass supports industrial furniture production lines. When used alongside cnc router table setups or industrial cnc router machines, it reduces idle time and enhances throughput. The automation ensures that factories producing cabinets, wardrobes, or panel-based furniture can maintain speed and quality simultaneously, meeting industrial demands for efficiency, accuracy, and repeatable results.

Use Scenarios

Cabinet And Wardrobe Production

The six-sided drilling system is suited to cabinets and wardrobes, where vertical and horizontal holes are required for hinges, dowels, and fasteners. In workshops also applying 4×4 cnc router or cnc router kits, this machine ensures precise drilling that simplifies assembly. Panels are prepared with consistency, enabling faster cabinet construction with fewer manual corrections.

Furniture panel processing:

For furniture manufacturers, this machine can drill and groove on six sides to produce panels suitable for mounting handle slots, connectors, or concealed fasteners. Integration with woodworking CNC engraving machines or CNC engraving machines increases flexibility and reduces setup time and manual operation. Ultimately, it improves product precision, helping manufacturers produce furniture with reliable connections and consistent quality.

In industrial woodworking production lines

, six-sided drilling machines are suitable for high-volume factories, supporting continuous production of wood-based furniture and door panels. They are highly automated, powerful, and can be seamlessly integrated with industrial CNC engraving machines or CNC machine tool engraving machines. A single drilling operation completes the processing of all sides, shortening the processing cycle and achieving uniform processing results, making it an indispensable tool in the industrial woodworking field where speed and precision are extremely important.

Machine advantage

High precision and easy to operate.

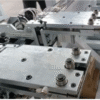

Automatic Feeding Device

Dual grippers

The double clamps automatically clamp the sheet metal into the machine

for processing.

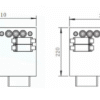

Grinding Screw

Z axis

The Z-axis is driven by a grinding leadscrew, and the leadscrew bearing

uses concentric bearings, resulting in a compact structure that effectively

ensures the precision of the equipment.

Double guide rails and double ball bearing guide rails can improve speed.

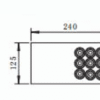

Bottom Drilling Package

9*1(1pcs)

Top Drilling Package

Vertical format: 9*1

Horizontal direction: X4*2 Y4*2 (2 units)

CONTACT US

If you have any queries, get in touch today! Don’t hesitate. We try to take the extra step for our customer satisfaction.

CONTACT US