SV-768J

Automatic EVA edge banding machine is a specialized piece of equipment used in the production of panel furniture,and it is to apply a strip of edge banding material (such as PVC, ABS, wood veneer, or melamine) to the exposed edges of panel materials like particleboard, MDF, or plywood. It primarily uses EVA hot melt adhesive to attach edge banding tape to the cut edges of the panels. Its core function is to achieve rapid, sealed, and aesthetically pleasing edge treatment of the panels.

Basic configuration

Workpiece length: ≥200mm

Workpiece width: ≥60mm

Workpiece thickness: 10-60mm

Covering tape thickness: 0.3-3mm

Working air pressure: 0.7Mpa

Total power :20KW

Machine size:8000*1000*1600mm

Function

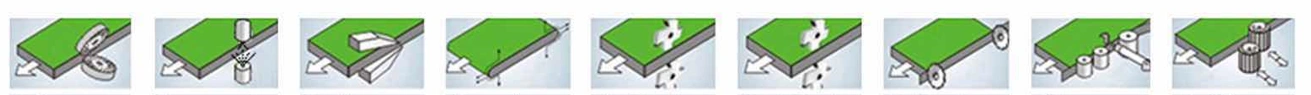

Separation-double motor pre-milling-Bottom EVA Gluing-6 Pressing rollers-Top gluing pot(EVA & PUR)-End cutting-Rough trimming-Fine trimming-Corner rounding–scraping-cleaning-Buffing-Buffing(Automatic lifting)

share:

Description

Automatic EVA edge banding machine is a specialized piece of equipment used in the production of panel furniture,and it is to apply a strip of edge banding material (such as PVC, ABS, wood veneer, or melamine) to the exposed edges of panel materials like particleboard, MDF, or plywood. It primarily uses EVA hot melt adhesive to attach edge banding tape to the cut edges of the panels. Its core function is to achieve rapid, sealed, and aesthetically pleasing edge treatment of the panels.

Main Functions

1. Sealing and Protection: Covers exposed surfaces of boards (such as particleboard and MDF) to prevent the release of moisture and harmful gases, and enhances moisture resistance.

2. Aesthetic Enhancement: Offers edge banding in various colors and textures, resulting in a cleaner and more visually unified furniture appearance.

3. Increased Durability: Reduces edge wear and impact damage, extending the lifespan of the furniture.

4. Safety Optimization: Rounded edges prevent scratches from sharp corners, improving safety during use.

Product Advantages

1. High Efficiency

Automated feeding, gluing, pressing, edge trimming, and polishing are completed in one continuous process, reaching speeds of 20-30 meters per minute, far exceeding manual operation.

2. High Precision and Stability

Utilizing a PLC or CNC system ensures a tight connection between the edge banding tape and the board, uniform glue seams, and reduced human error.

3. Cost-Effectiveness

Reduces reliance on skilled workers, minimizes glue waste, and significantly saves on labor and material costs in long-term production.

4. Flexibility

Adaptable to edge banding tapes of different thicknesses and materials (such as PVC, ABS, etc.), allowing for the processing of rounded edges and right-angled edges by changing accessories.

5. Environmental Improvement

Enclosed glue tanks reduce glue evaporation, and some models are equipped with dust collection devices, reducing workshop pollution.

Use Scenarios

1. Mass Production of Panel Furniture

Suitable for large-scale manufacturing of furniture such as cabinets, wardrobes, and desks, with a particular emphasis on efficiency and consistency.

2. Whole-House Customization Factories

Meeting the need for rapid changeover to personalized orders, adapting to flexible production of multiple specifications and small batches.

3. Building Materials and Interior Decoration

Used for edge finishing of products such as wooden doors, wall panels, and display cabinets, enhancing product quality.

4. Industrial Support Sector

Edge encapsulation of industrial products such as appliance cabinets, laboratory equipment, and automotive interior parts.

Machine advantage

1.Taiwan Shilin PLC,Taiwan Shilin Inveter ,Taiwan Shilin touch screen and Schneider contactor to ensure machine working stable.

2.Pressing rollers with flat knife,to make more perfect edge banding surface.

3.Heavy duty machine body to ensure machine is dural.

4.Good price.

5.PUR gluing and pneumatic adjuting cutter tooling are optional.

Full Automatic PVC Edge Banding Machine SV-468J Touch Screen

Taiwan China Shilin Brand

PLC and Inveter

Taiwan China Shilin Brand

Famous Brand Contactor

Franch Schneider brand

Reliability & Durability & Safety.

Dual Motors Pre-milling

2.2kw x2 pcs

Press Rollers With Scraper

6 pressing rollers

It makes the pressing more perfect,rubber roller will make pressing more even.

Double Trimming

Rough trimming & fine trimming

Corner Rounding

2 heads corner rounding

Dual motor tracking, used for arc trimming of corners.

Using 0.37*2 motor.

4-head corner rounding is optional.

Scraping and buffing

Scraping and dual motor buffing

After trimming, scrape off the residue on the board and edge band again to ensure that the board and edge band are smooth and clean, making the edge band effect smoother. The polishing and waxing device effectively solves the problem of whitening of the edge band, making the edge band effect more perfect.

Edge Banding Effect

0.4-3MM is available

Good edge banding effects make your furniture better.

Top gluing tank

PUR glue and EVA glue

This kind of gluing tank is suitable for processing EVA glue and granular PUR glue.

Top fast melt gluing tank is only for EVA glue,save glue melting time with automatic feeding glue function.

CONTACT US

If you have any queries, get in touch today! Don’t hesitate. We try to take the extra step for our customer satisfaction.

CONTACT US