4S2H4W

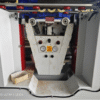

Automatic 4 Side Sanding Machine 4S2H4W is automatic sanding machine for wood strips,professional for sanding wooden flooring, door frame, picture frame and ect. It can be for sanding before painting and for primer sanding.

Basic configuration

Processing width range:50-150mm

Minimum processing length:680mm

Processing thickness range: 15-100mm

Feeding speed (frequency conversion speed regulation) :3-40m/min

feeding motor power: 4.95kw

Triangular sand frame motor :4 sets 3kw

Triangular sand frame swing motor: 4 sets 0.09kw

Triangular sand frame sand belt: 1680×170mm 1680×120mm

Dual-purpose sand frame Main motor: 2 2.2kw

Sand frame sand belt size (circumference × width): 1010×150mm

Spindle rotation adjustable Angle :0°~180°

Grinding head motor: 2 2.2kw 2 1.5kw

Spindle size (shaft length × length): 25.4×150mm*2 25.4×100mm*2

Grinding wheels Maximum installation size (diameter × thickness) :200×150mm

Spindle configuration 6 sets

Dust outlet diameter :98mm

Working pressure: 0.6Mpa

Total power: 29.11kw

Independent electric box size :1130*550*1500mm

Mechanical dimensions: 6250 *1500 * 1600mm

Function

share:

Description

Multi-Head Sanding for Wood Strip Processing

Automatic 4 side sanding machine is equipped with 10 sanding heads, including triangular racks, dual-purpose racks, and flying wing wheel heads, designed for sanding wooden flooring, door frames, picture frames, and other solid wood strips. Each head is controlled by variable frequency speed regulation, providing flexibility in handling different workpiece profiles. Automatic air blowing functions keep sanding belts clean, improving consistency during continuous use. Manufactured by a professional cnc router manufacturer, it illustrates how automation reduces manual adjustments. The equipment demonstrates standards expected from established woodworking cnc machine manufacturers, combining technical precision with practical performance.

Precision Adjustment with Automated Functions

The system integrates automatic compensation, variable frequency speed transmission, and pneumatic pressing for stable sanding results. Grinding spindles allow angle adjustment between 0° and 180°, meeting the needs of complex surfaces. Triangular sand racks with swing motors imitate sanding of special-shaped straight edges, while telescopic functions protect the ends of workpieces. Operators manage functions easily through a touch screen, with separated electrical boxes for simpler transport and installation. These features highlight Samdy’s role as a cnc wood router supplier committed to stability and precision. It also reflects the engineering detail valued by router cnc users managing diverse workloads.

Structural Durability with Flexible Operation

The machine body is designed with reinforced strength and stability, ensuring dependable operation during industrial-scale workloads. It supports processing widths from 50 to 150 mm, thicknesses between 15 and 100 mm, and lengths of at least 680 mm. Feeding speeds range from 3 to 40 meters per minute, supported by frequency regulation and a 4.95 kW motor. With dust outlet connections at 98 mm, safe operation is maintained throughout sanding cycles. Delivering a total power of 29.11 kW, the system combines efficiency with durability. This reflects Samdy’s expertise, also seen in 4×8 cnc router solutions, extending its capabilities to meet woodworking cnc machine requirements for heavy-duty production.

Use Scenarios

Flooring Strip Surface Preparation

The sander is designed for sanding solid wooden flooring strips, ensuring surfaces are smooth before painting or coating. With multiple head types, it can manage straight edges and detailed profiles. This makes it a practical option from a trusted cnc table router supplier. Samdy’s experience as a cnc router aluminum manufacturer strengthens its role in supporting flooring industries with consistent sanding solutions.

Door and Frame Manufacturing

Door frames and picture frames often require sanding before primer application. The combination of triangular and sponge sanding heads provides accuracy for detailed edges and corners. This versatility reflects the adaptability expected from a large cnc router manufacturer. With technology extended from its cnc router for aluminum expertise, Samdy delivers equipment suitable for workshops handling high-precision frame production.

Continuous Industrial Sanding Lines

With a conveyor speed range of 3–40 m/min, the machine supports integration into continuous sanding lines. Automatic cleaning and compensation functions reduce downtime, ensuring smooth operation in industrial settings. This aligns with the reliability users expect from advanced cnc router machines. By combining automation with robust construction, Samdy proves its capability as a cnc woodworking machine manufacturer supporting professional-scale production.

Machine advantage

1) 400 sand racks (3KW) × 4 units; dual-purpose sand racks (2.2KW) × 2 units, flying wing wheel sanding heads (2.2KW) × 2 units; flying wing wheel sanding heads (1.5KW) × 2 units;

2) Each grinding head is controlled by variable frequency speed regulation, and the sand rack has an automatic air blowing function;

3) The grinding head has automatic compensation (automatically presses down);

4) Variable frequency speed regulation transmission; pneumatic wheel type material pressing;

5) Touch screen control; For easy transportation, the eltrical box and equipment are separated and are independent .

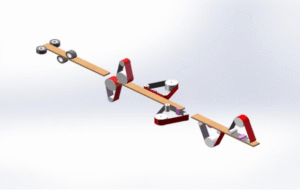

Sanding heads

10 sanding heads layout

Different sanding heads matched together to achieve processing different shape working pieces.

400 triangle sanding head

Sanding belt

The sanding belt has an automatic swing function; the pressing module can imitate the sanding of special-shaped straight edges; and it has an automatic telescopic function to protect the head and tail of the workpiece; the operation is simple, and more features: the grinding amount is the strongest, and the flatness is the best

Sponge sanding head

Dual usage

The sanding head is compatible with the universal standard grinding wheel. It can be equipped with brush sand rollers, octagonal sand, grinding wheels, polishing wheels and other abrasives to implement all-round and diversified sanding of special-shaped parts. It is easy to operate and convenient to replace sanding belts and abrasives. It also has an automatic telescopic function to protect the head and tail of the workpiece, and automatic compensation using grinding wheels. Features: good versatility for processing surfaces, strong abrasive matching, and can sand any special-shaped surface.

Heavy duty machine body

Machine advantage

According to different process requirements, various sand heads can be freely arranged and configured

◆ Sand head and sand rack can be adjusted from -90° to +90°, suitable for linear profiling sanding

◆ Sand rack has an oscillation device, sand head has automatic compensation function, induction advance and retreat function, to ensure that the workpiece head and tail are not sanded through or rounded

◆ Pressing material adopts pneumatic pressing material, spring load, reliable pressing material, no damage to the workpiece.

◆ PLC precise control, easy adjustment.

◆ Conveying and sand belt speed adopt frequency conversion speed regulation to suit the corner sanding of different wood products; (white embryo, primer)

◆ Different power motors and abrasives of various shapes and functions can be selected according to different shapes

Sanding material

Sanding belt and sanding sponge

It can meet different working shapes’s requirement.

Working piece shape

4 sides sanding

Sanding head and sand rack can be adjusted from -90° to +90°, suitable for different shapes.

CONTACT US

If you have any queries, get in touch today! Don’t hesitate. We try to take the extra step for our customer satisfaction.

CONTACT US