3 Heads CNC Side Drilling Machine is a specialized piece of equipment primarily used in woodworking, cabinetry, panel processing, and furniture manufacturing. It automates the precise drilling of holes perpendicular to the surface (side holes) or at specific angles into the edges of panels or workpieces.

Basic configuration

Max working thickness:60mm

Max working length:2700mm

Max working width:140mm

Working table size:500*2800mm

Working speed:60m/min

Vertical spindle:3.5kw *2

Horizontal spindle:3.5kw*1

Total power:12.25kw

Machine size:3600*1450*1300mm

Machine weight:1200kg

Function

Drilling side holes, grooving, drilling U-shaped invisible parts and special-shaped workpieces, eliminating the need for handles, etc.

share:

Description

Multi-Head Drilling System For Panel Processing

3 heads CNC side drilling machine is configured with three independent drilling heads, providing capacity to process hardware mounting holes and free handle grooving on wooden panels. It supports a maximum workpiece size of 2700×140×60 mm and achieves feed speeds up to 60 m/min. Each spindle is powered by 3.5 kW, delivering accuracy and efficiency for high-volume furniture and cabinet production. The system complements cnc router or cnc router machine operations by covering drilling tasks that cannot be completed during routing. This integration ensures panels are fully prepared for assembly without additional manual work.

Stable Structure With Integrated Control

Built with a heavy-duty frame, the machine provides reliable performance and reduced vibration for consistent drilling. It is equipped with a simple control interface and optimized layout to improve usability in daily production. Total power of 12.25 kW supports continuous operation, while the structure enables alignment with panel workflows in furniture, door, and cabinet factories. This stability allows facilities using woodworking cnc machine manufacturers solutions or cnc woodworking machine setups to incorporate drilling functions without disrupting routing or cutting tasks. The system’s design ensures efficient cooperation between drilling and broader machining lines.

Applications Across Furniture And Cabinet Lines

The three-head configuration supports multiple drilling patterns simultaneously, improving speed and reducing processing time. This is especially suitable for cabinet side panel drilling, wooden frame hole processing, and furniture handle slotting. By focusing on automation of repetitive operations, the machine enables smoother integration with cnc router table setups or industrial cnc router systems. Manufacturers benefit from reduced manual marking, accurate hole positioning, and faster assembly preparation, ensuring panel products meet quality standards for durability and functionality in industrial-scale woodworking environments.

Use Scenarios

Cabinet Panel Drilling

Ideal for cabinet side panels, the machine processes multiple hardware mounting holes and grooves with precision. In facilities that also use 4×4 cnc router or cnc router aluminum setups, it ensures panels are fully prepared for assembly. The ability to automate drilling reduces reliance on manual measurement and speeds up cabinet production, improving overall accuracy and consistency.

Furniture Frame And Handle Grooving

For furniture workshops, the machine provides accurate handle slotting and frame drilling, allowing manufacturers to deliver panels with complete assembly-ready features. When combined with woodworking cnc router equipment or cnc router machines, it adds value by automating complex repetitive drilling. This reduces manual errors while supporting the production of durable, functional wooden furniture at industrial scale.

Large Industrial Production Environments

In high-volume panel factories, the three-head system helps maintain output speed while ensuring quality. Facilities equipped with industrial cnc router units or cnc drilling machine solutions can integrate this side drilling machine into existing lines. It supports continuous use through its strong structure and high-power spindles, aligning with the requirements of modern woodworking industries where efficiency, stability, and accuracy define competitive performance.

Machine advantage

1. Drilling Shelf Pin Holes: Creating the precise grid of holes in cabinet side panels for adjustable shelves.

2. Drilling Hardware Mounting Holes: Holes for hinges, drawer slides, handles, connectors (cam locks, dowels, minifix), and other cabinet/furniture hardware on panel edges.

3. Drilling System Holes: Essential for 32mm cabinet system construction.

4. Angled Drilling: Creating holes for specialized joints or hardware requiring non-perpendicular holes.

5. Pre-Drilling for Assembly: Creating holes for screws, dowels, or other fasteners used in joining panels together.

6. Ventilation/Drainage Holes: Drilling patterns of holes for functional purposes.

Drilling Spindle

3 spindles (2 horizontal heads +1 vertical heads)

3 spindles to process a variety of products.(3.5kw*2+2.2kw *1)

Automatic Tool Setting

Vertical

Automatic positioning to ensure processing accuracy.

Position Cylinder

Movable pressing cylinder

8 groups of movable pressing cylinder to make sure pressing panel well during processing.

Precision Screw

High precision and stable

Screw drive ensures the accuracy and stability of machine processing.

Control System

Touch screen

Touch screen control system, easy to operate.

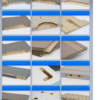

Finished Products

Multiple functions

Can process a variety of products to meet all your cabinet processing requirements.

CONTACT US

If you have any queries, get in touch today! Don’t hesitate. We try to take the extra step for our customer satisfaction.

CONTACT US